Square hvac ventilation galvanized sheet metal TDF/TDC air duct clamping flange roll clip making maker former forming machine

- Model

- T-12

Item specifics

- color

- yellow and Blue

- Material

- Steel

- Application

- Air duct industry/Metal products industry

- Sheeting Thickness

- 0.5-1.2mm

Review

Description

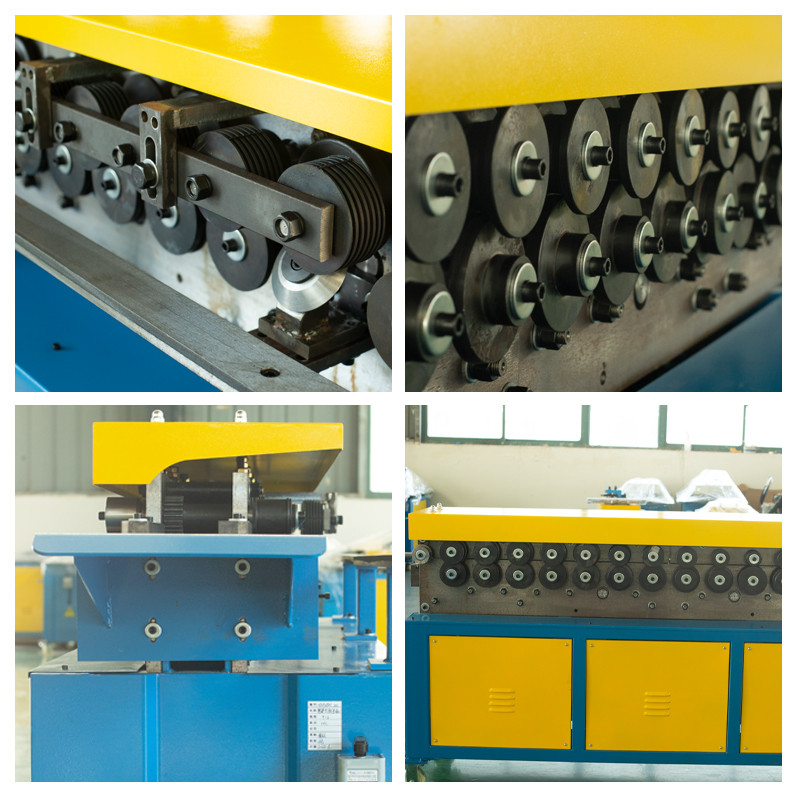

Tdf flange forming machine Description

TDF flange forming machine is flange forming in the duct connection port of special equipment. Tdf flange forming machine is suitable for ventilation ducts with small cross-sectional area. It has good sealing performance and low cost. It is equipped with 16 pairs of forming rollers and 2 forming stations. The flange heights are 20mm, 34mm and 40mm. Standard The station is used to make the TDF common plate flange, and the auxiliary station is used to make the flange card code (flange clamp), that is, while forming the flange, the card code is formed at the same time, so as to achieve dual functions of one machine.

Main Technical Parameters

|

Modle

|

Sheet thickness(mm)

|

Dimensions(m) L*W*H | Power(kw) |

Weight (kg) |

|

T-12

|

0.5-1.2

|

2550*700*1100 | 3 |

840

|

|

T-15

|

0.8-1.5

|

2550*700*1100 | 3 |

840

|

Machine details

Precautions

- Safety usage: Before using the Auto Air Duct Production equipment, it is necessary to carefully read and comply with the manufacturer's instructions for use and follow the safety operating procedures of the equipment to ensure personal safety and normal operation of the equipment.

- Maintenance: Regular maintenance of the Auto Air Duct Production equipment is necessary to ensure long-term stable operation. Cleaning and lubricating various parts of the equipment, and replacing worn parts are important maintenance contents.