Stainless Steel Metal Sheet Electric Type Folding Machine

Item specifics

- color

- yellow and Blue

- Material

- Steel

- Application

- Air duct industry/Metal products industry

- Sheeting Thickness

- 1.5mm

Review

Description

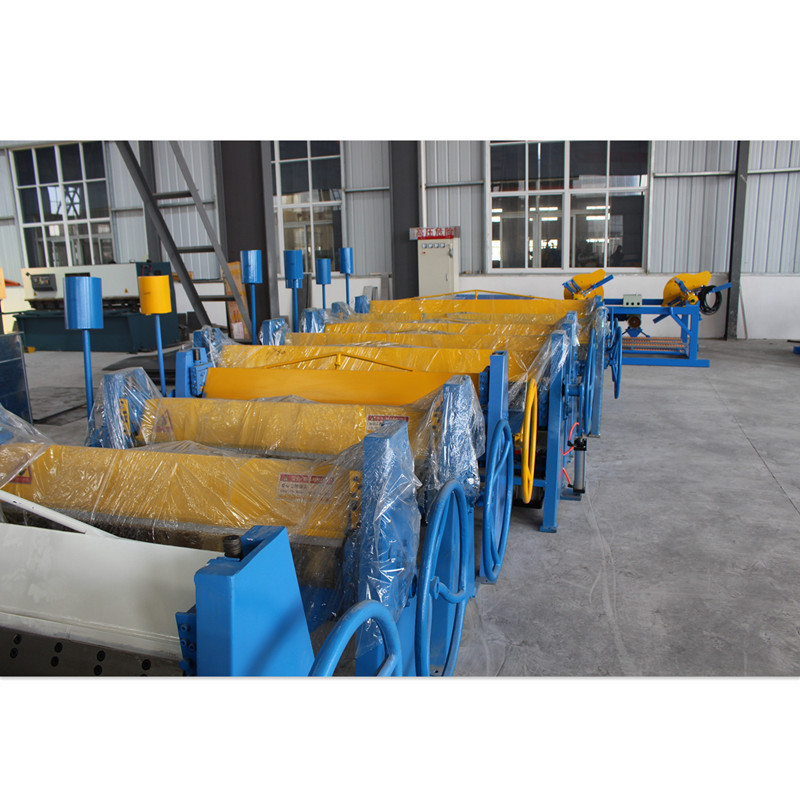

Electric Folding Machine Description

Electric folding machine is one of the modern equipment for thin sheet metal processing,professional for the bending process of thin plates, with light weight,simple operation,convenient transportation,more suitable for short-term temporary site bending processing, can be used in many environment. The length can be customized according to customer.

Main Technical Parameters

|

Modle

|

Plate Thickness(mm) | Max.Plate width (mm) |

Folding Angle

|

Dimensions(mm) L*W*H |

Weight(kg) |

|

WS-1.5*1300 |

0.3-1.5 | 1300 |

90°

|

1980*800*1320 |

360

|

|

WS-1.5*1500 |

0.3-1.5 | 1500 |

90°

|

2180*800*1320 |

380

|

WS-1.5*2000 | 0.3-1.5 | 2000 | 90° | 2680*800*1320 | 440 |

WS-1.5*2500 | 0.3-1.5 | 2500 | 90° | 3180*800*1320 | 560 |

WS-1.2*3000 | 0.3-1.2 | 3000 | 90° | 3860*800*1590 | 680 |

TDF-1.5*1500 | 0.3-1.5 | 1500 | 90° | 2180*800*1320 | 450 |

TDF-1.5*2000 | 0.3-1.5 | 2000 | 90° | 2680*800*1320 | 550 |

TDF-1.5*2500 | 0.3-1.5 | 2500 | 90° | 3180*800*1320 | 660 |

Performance Features

1. Heavy duty steel fabricated frame provides accurate bends

2. Extended fingers allows bending of pans or boxes to a depth of 200mm

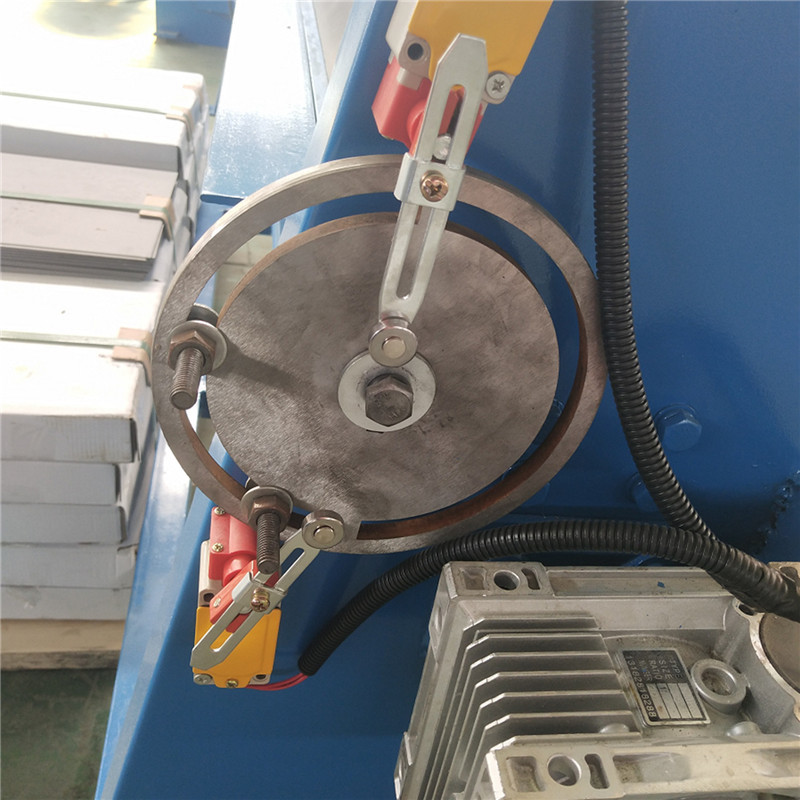

3. Machine equipped with a graduation ruler on both sides, readout eliminates the bend angle guess work

4. Ground segmented fingers can be repositioned to suit many applications

5. Safety top beam support stop lever located on right side of machine

6. Quick action beam adjustment for varying material thickness

7. Includes rear manual back gauge

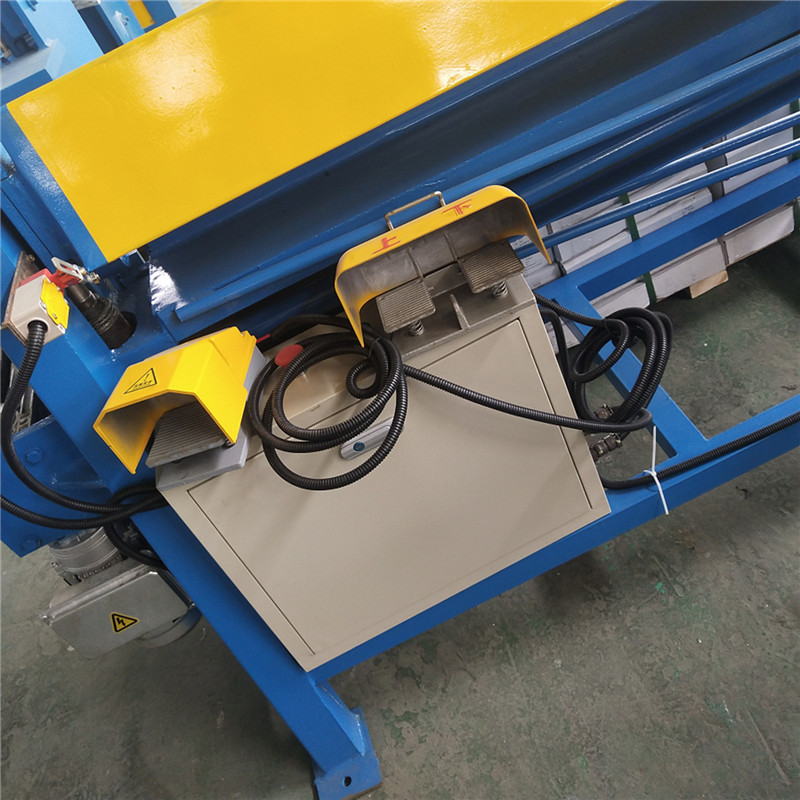

Machine details

Precautions

- Safety usage: Before using the Auto Air Duct Production equipment, it is necessary to carefully read and comply with the manufacturer's instructions for use and follow the safety operating procedures of the equipment to ensure personal safety and normal operation of the equipment.

- Maintenance: Regular maintenance of the Auto Air Duct Production equipment is necessary to ensure long-term stable operation. Cleaning and lubricating various parts of the equipment, and replacing worn parts are important maintenance contents.