Square HVAC Air Auto Duct Production Line 3 Machine for Rectangular Duct

Item specifics

- color

- yellow and Blue

- Material

- Steel

- Application

- Air duct industry/Metal products industry

- Sheeting Thickness

- 0.5-1.5mm

Review

Description

Auto Air Duct Production Line 3 Description

Auto duct production line 3 can drive blanking for duct. Meantime, it’s very suitable for multi-production like TDF/angle steel/inserted flange forming; the angle steel flange and inserted flange can be bent into square-shaped pipe automatically.

Main Import Configuration

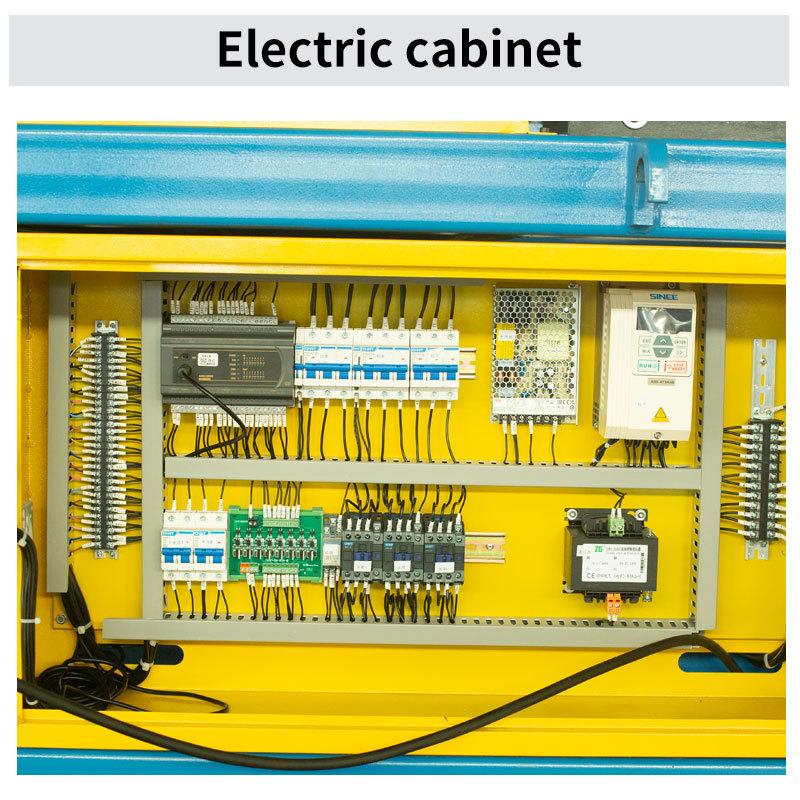

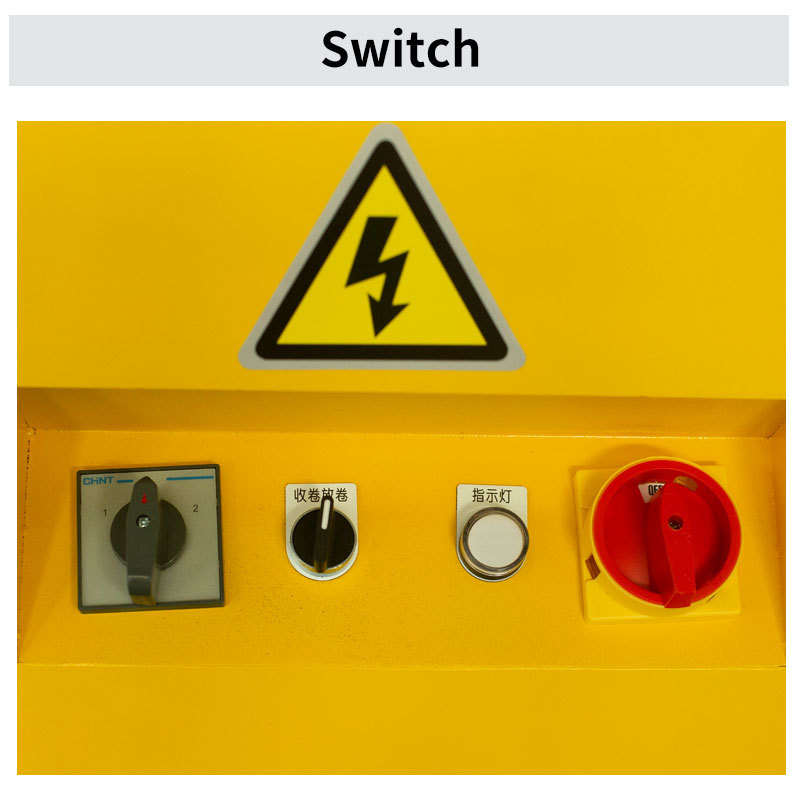

1. Germany Siemens/Mitsubishi CNC system +Schneider electrical system

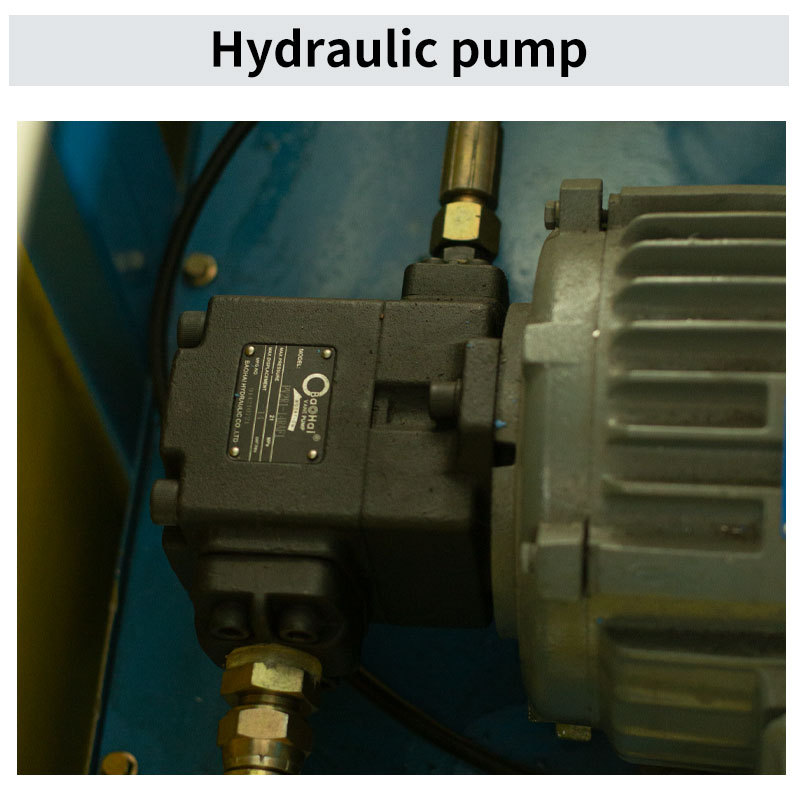

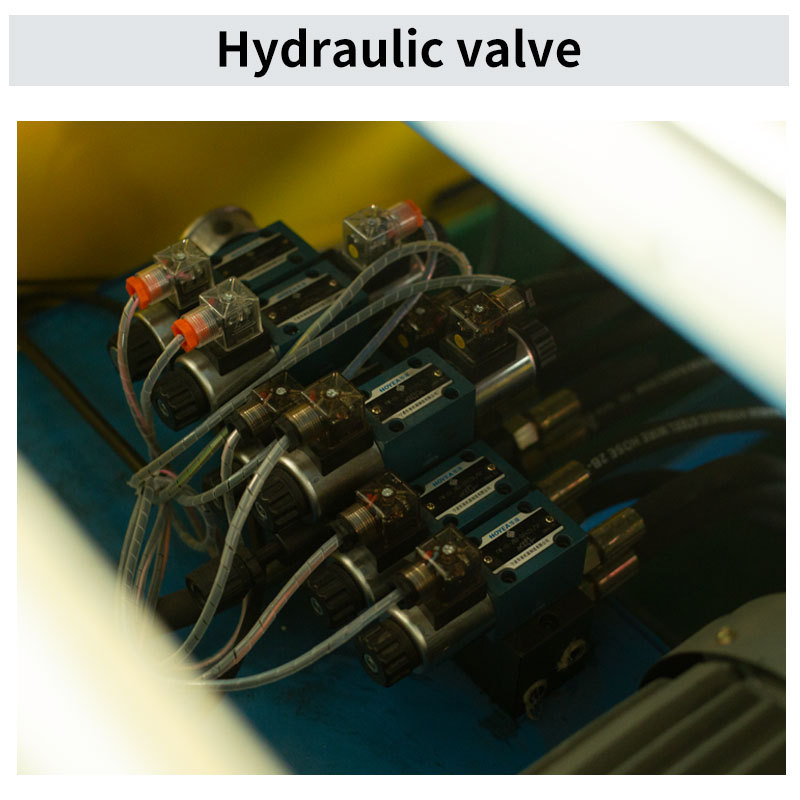

2. Beijing Huade or hydraulic system from Taiwa

3. Japan Omron encoder

Basic Configuration

1. One electric coil cradle (two material trays)

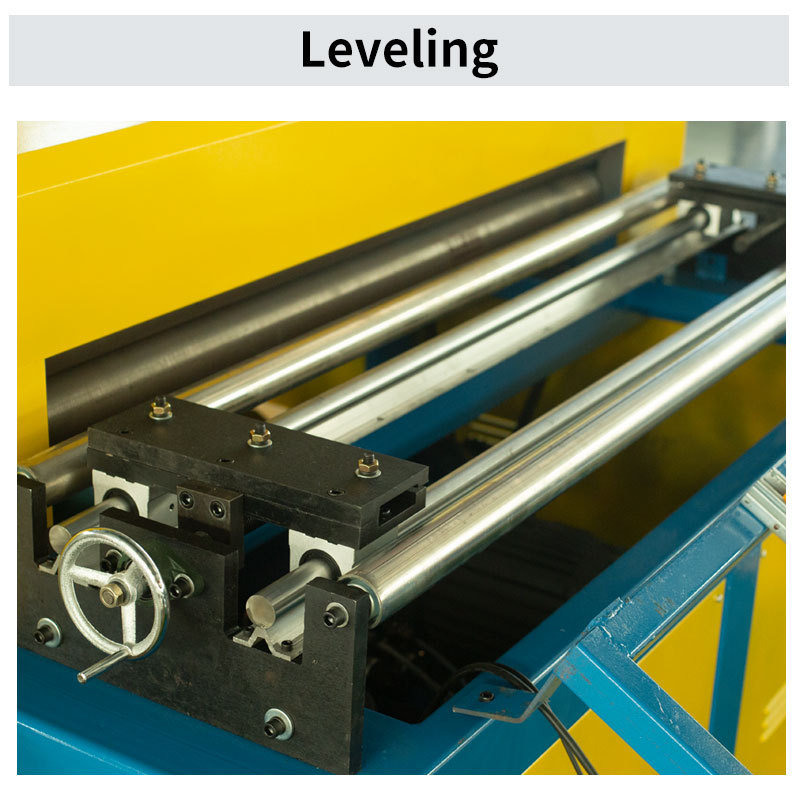

2. One set of leveling and beading equipment

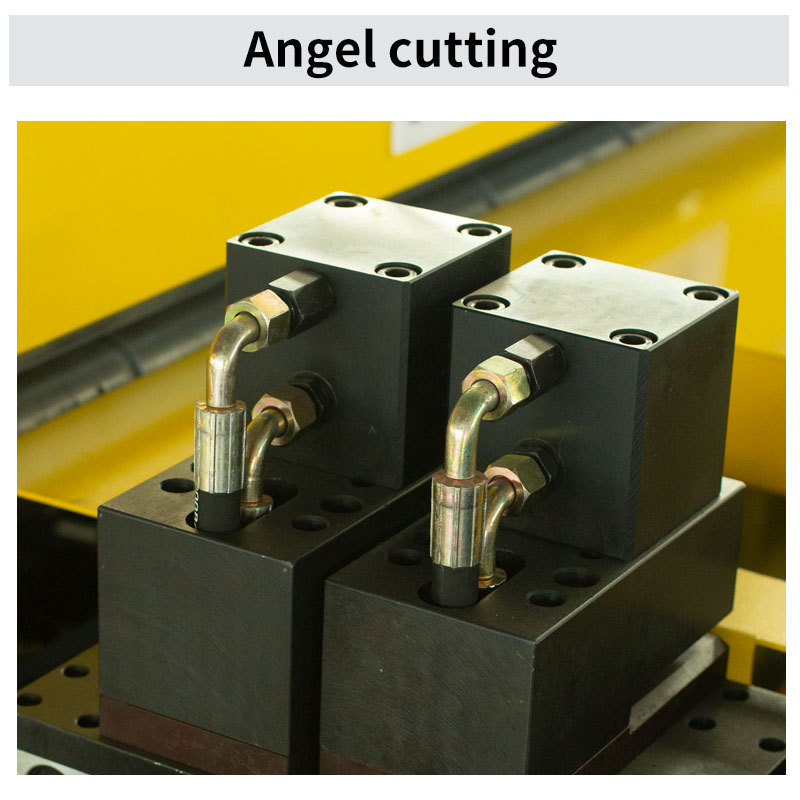

3. Hydraulic angle-shearing machine with four sets of die

4. Hydraulic sheet-shearing machine, hydraulic bending machine, hydraulic press machine

5. A set of CNC computer control system and production software

Main Technical Parameters

|

Modle

|

Sheet thickness(mm)

|

Max width(mm)

|

Max working speed(m/min) | Coiler max weight(T) | Dimensions(m) L*W*H | Power(kw) |

Weight (T) |

|

ADL-3-1250

|

0.5-1.2

|

1250

|

15 | 7 | 2200*1950*1300 2500*1950*1600 | 8 |

3.5

|

|

ADL-3-1500 |

0.5-1.2

|

1500

|

15 | 7 | 2200*2150*1300 2500*2150*1600 | 8 |

4

|

Machine details

Precautions

- Safety usage: Before using the Auto Air Duct Production equipment, it is necessary to carefully read and comply with the manufacturer's instructions for use and follow the safety operating procedures of the equipment to ensure personal safety and normal operation of the equipment.

- Maintenance: Regular maintenance of the Auto Air Duct Production equipment is necessary to ensure long-term stable operation. Cleaning and lubricating various parts of the equipment, and replacing worn parts are important maintenance contents.