Optimizing Duct Manufacturing with the Auto Duct Production Line 5

Item specifics

- color

- yellow

- Material

- Steel

- Application

- Air duct industry/Metal products industry

Review

Description

Auto Air Duct Production Line 5 Description

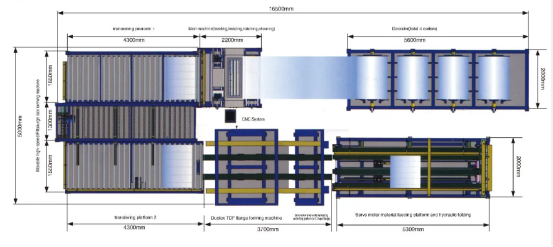

Auto Duct Production Line 5 is mainly for TDF/angle steel/C-shaped flange forming with daily processing capability of 1000-2500 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling , leveling, beading, punching,shearing, locking, forming TDF/angle steel/C- shaped flange and folding.

Main Import Configuration

1.Beijing Huade plus hydraulic system from Taiwan

2.Japan Omron encoder

3.Taiwan Hiwin linear guideways

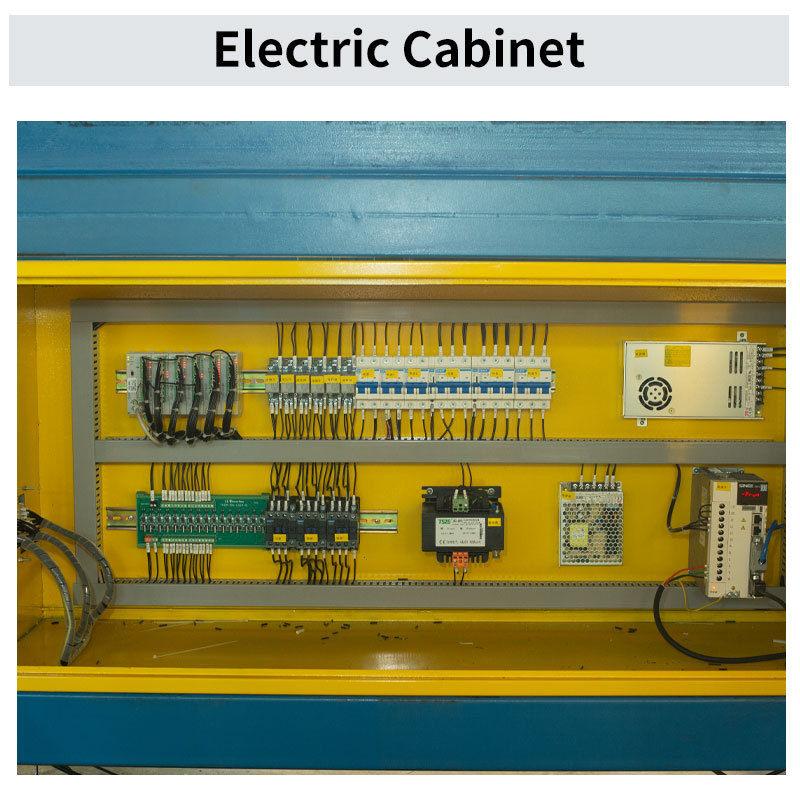

4.Schneider electrical system

Basic Configuration

1.Two electric coil cradles, 4 material trays (5-7t each roll)

2.One rack

3.One host (line 2 host)

4.Two stainless steel roller conveyer platforms

5.One fixed joint locking machine

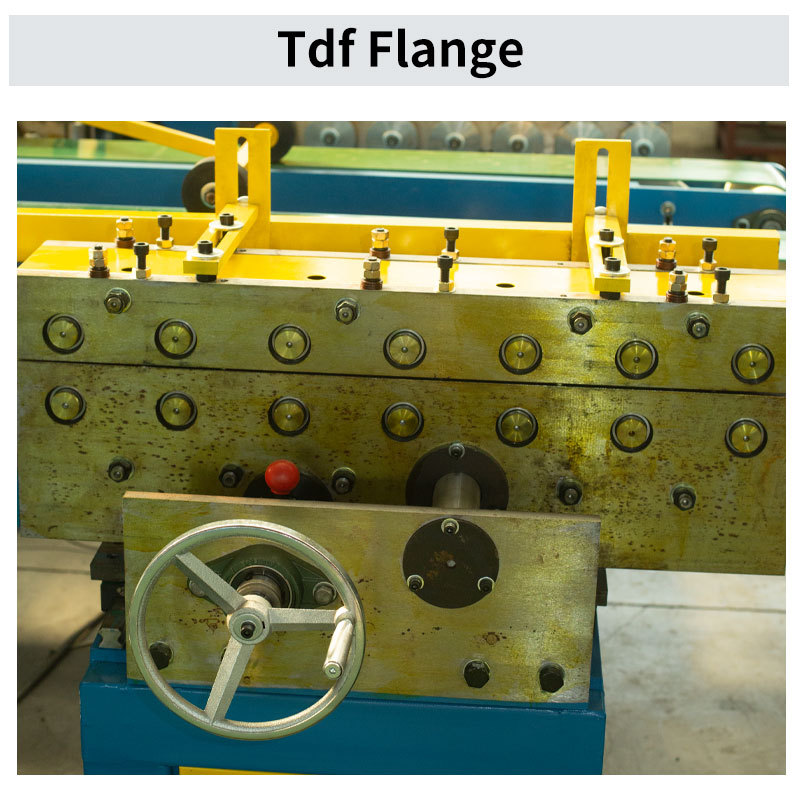

6.One duplex TDF flange forming machine

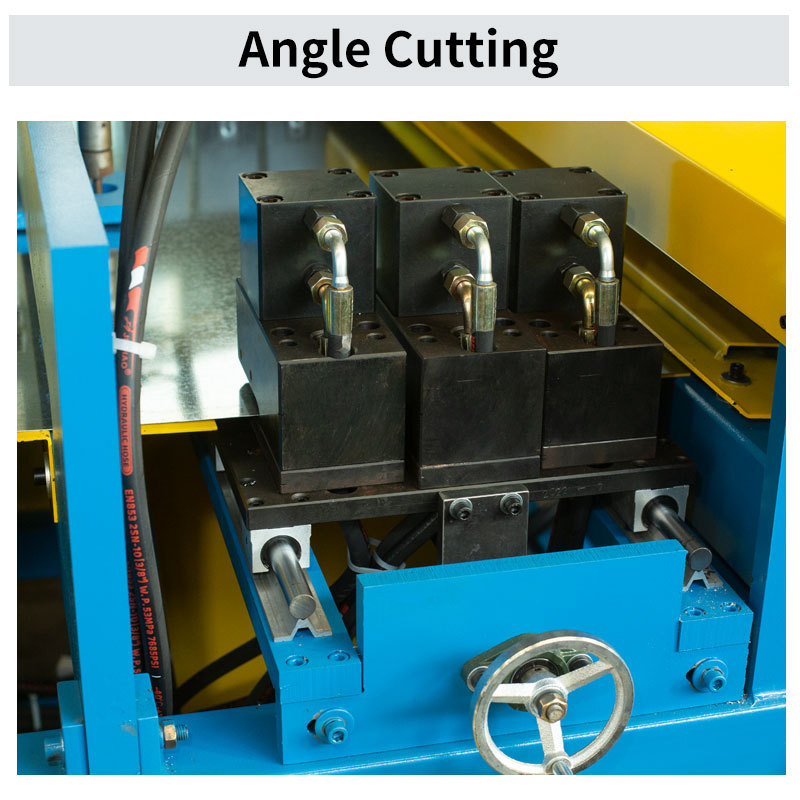

7.One duplex angle steel flange forming machine

8.One servo feeding platform

9. One hydraulic folding machine

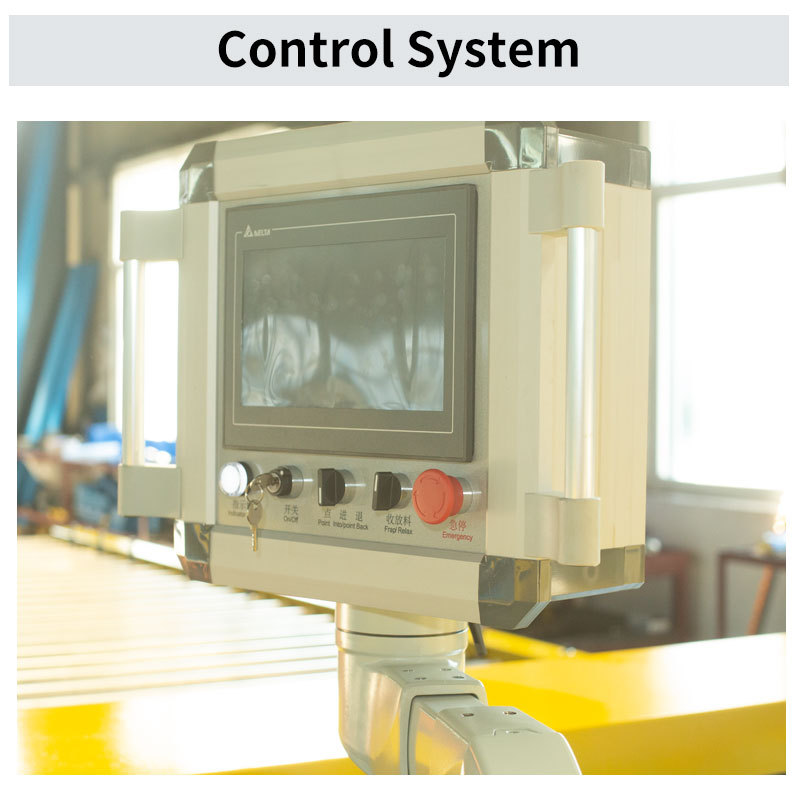

10.One set of computer controlling system

Main Technical Parameters

|

Modle

|

Sheet thickness(mm)

|

Max width(mm)

|

Max working speed(m/min) | Coiler max weight(T) | Dimensions(m) L*W*H | Power(kw) |

Weight (T) |

|

SADL-5U-1250

|

0.5-1.2

|

1250

|

15 | 7 | 16500*5000*1500 | 30 |

13

|

|

SADL-5U-1500

|

0.5-1.2

|

1500

|

15 | 7 | 16500*5400*1500 | 30 |

14

|

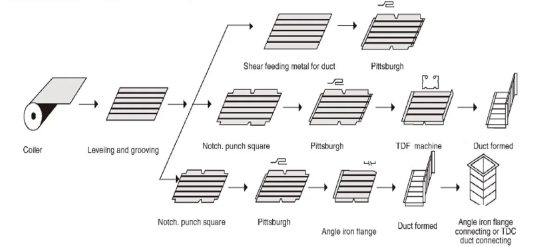

Working Schematic Diagram

Work Flow

Machine details

Application

Air duct industry

Metal products industry

Precautions

- Safety usage: Before using the Auto Air Duct Production equipment, it is necessary to carefully read and comply with the manufacturer's instructions for use and follow the safety operating procedures of the equipment to ensure personal safety and normal operation of the equipment.

- Maintenance: Regular maintenance of the Auto Air Duct Production equipment is necessary to ensure long-term stable operation. Cleaning and lubricating various parts of the equipment, and replacing worn parts are important maintenance contents.